INDUSTRIAL VALVES

Coteso offers a comprehensive range of industrial valves designed to meet the diverse needs of various industries, including oil and gas, petrochemical, power generation, water treatment, and more.

Our valves are manufactured to the highest standards of quality and performance, ensuring reliability, safety, and efficiency in demanding applications.

Our valves are manufactured to the highest standards of quality and performance, ensuring reliability, safety, and efficiency in demanding applications.

We have been providing our customers with comprehensive service for many decades and are able to realize tailor-made valve solutions. We have an extensive and excellent track record of valves supplied to several industries.

We are proud to confirm that all our engineered products meet the highest international quality standards and have been operating successfully in different terminals and industries around the world, to great satisfaction of our customers.

A close cooperation with leading manufacturers together with a well-balanced portfolio of our own engineered and manufactured products results in a strong partner for all your industrial valve requirements.

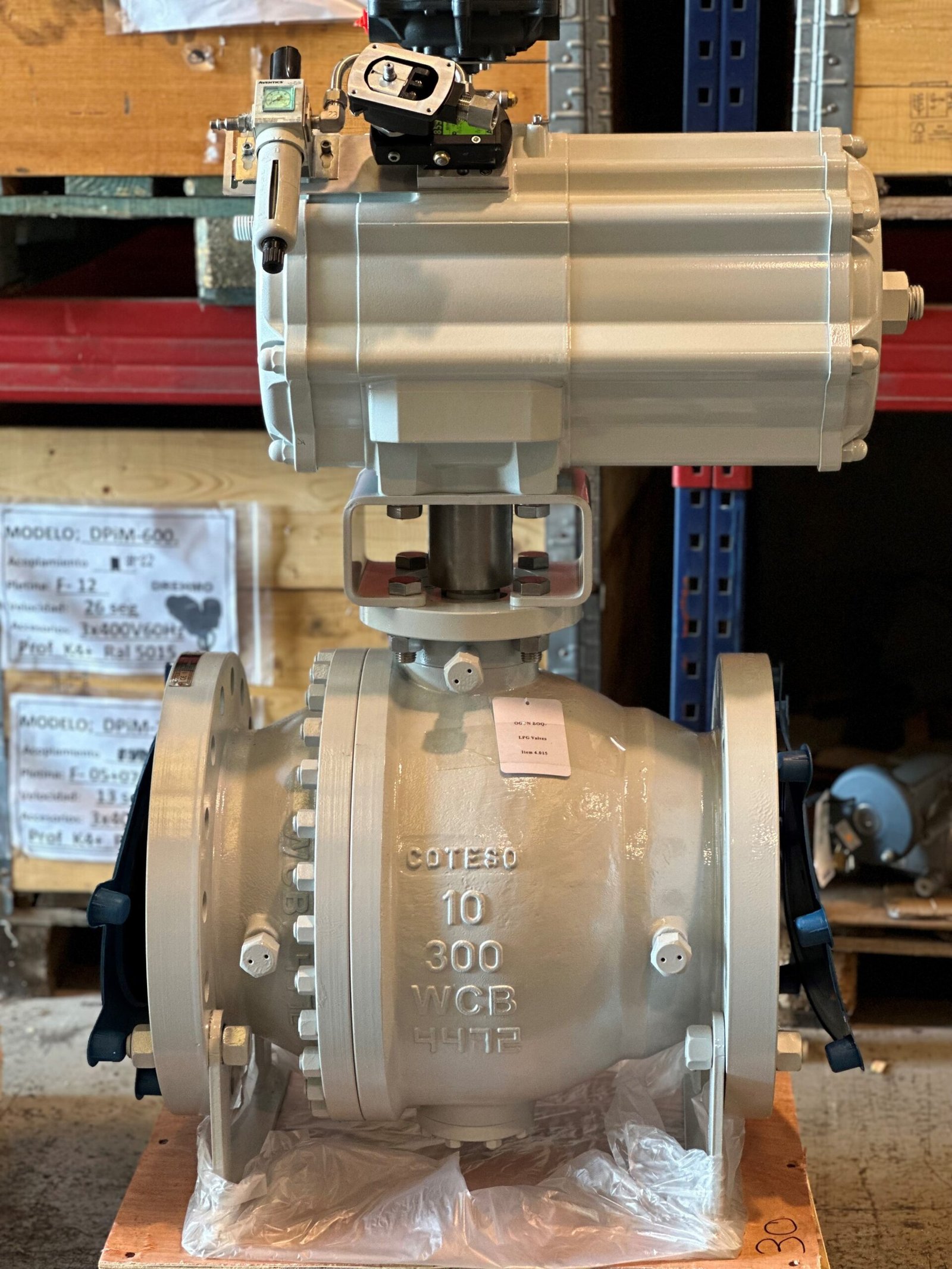

We are also able to provide motorized valves and all types of actuators upon the customers request and specifications, where we are able to provide world leading actuator brands and support you with calibration and installation when required.

TYPES OF INDUSTRIAL VALVES

Ball Valves

Ball valves are widely used for their durability and reliable sealing. They are ideal for quick shutoff applications and are designed to provide tight sealing with low torque operation.

Features and Benefits:

- Durability: Made from high-quality materials to withstand harsh conditions and corrosive environments.

- Tight Sealing: Provides excellent sealing performance, preventing leaks and ensuring operational safety.

- Low Maintenance: Designed for long service life with minimal maintenance requirements.

- Versatility: Suitable for a wide range of applications, including gas, liquid, and slurry.

Applications:

- Used in pipelines, process control, and fluid handling systems across various industries.

Gate Valves

Gate valves are primarily used to start or stop the flow of liquid when a straight-line flow of fluid and minimum flow restriction are needed.

Features and Benefits:

- Full Flow: Offers minimal pressure drop when fully open, ensuring efficient flow.

- Durability: Robust construction for long-term reliability in demanding environments.

- Easy Operation: Simple design for easy operation and maintenance.

- Wide Range: Available in various sizes and materials to suit different applications.

Applications:

- Commonly used in water treatment, oil and gas, and power generation industries.

Globe Valves

Globe valves are used for regulating flow in a pipeline, offering precise control over the flow rate.

Features & Benefits

- Flow Control: Provides accurate control over fluid flow, making it ideal for throttling applications.

- Durability: Made from materials that ensure long-lasting performance and resistance to wear.

- Versatile Design: Suitable for various applications requiring precise flow regulation.

- Ease of Maintenance: Designed for easy disassembly and maintenance.

Applications:

- Used in process control systems, steam systems, and other applications requiring flow regulation.

Check Valves

Check valves are designed to prevent backflow in a piping system, ensuring unidirectional flow of fluids.

Features and Benefits:

- Backflow Prevention: Ensures that fluid flows in only one direction, protecting equipment and maintaining process integrity.

- Low Pressure Drop: Designed to offer minimal resistance to flow, ensuring efficient operation.

- Durable Construction: Made from robust materials to withstand high pressures and temperatures.

- Maintenance-Free: Typically requires little to no maintenance, reducing operational costs.

Applications:

- Widely used in water supply systems, oil and gas pipelines, and chemical processing.

Butterfly Valves

Butterfly valves are used for isolating or regulating flow, known for their compact design and quick operation.

Features and Benefits:

- Compact Design: Space-saving design makes it ideal for installations with limited space.

- Quick Operation: Allows for rapid opening and closing, enhancing operational efficiency.

- Versatility: Suitable for a wide range of applications, including water, air, gas, and chemicals.

- Cost-Effective: Economical solution for flow control in various systems.

Applications:

- Commonly used in water treatment, HVAC systems, and food processing industries.

Design and Manufacturing Standards

Coteso’s industrial valves are designed and manufactured to meet the following standards:

- API Standards: Ensures compliance with the American Petroleum Institute standards for valve design and performance.

- ASME: Adherence to the American Society of Mechanical Engineers standards for pressure vessel components.

- ISO Standards: Compliance with relevant ISO standards for quality management and environmental protection.

Key Components

- Body and Bonnet: High-quality materials ensuring durability and resistance to corrosion and wear.

- Seats and Seals: Designed to provide tight sealing and prevent leaks, ensuring safe and efficient operation.

- Actuators: Options for manual, pneumatic, and electric actuators to suit different operational needs.

- Stems and Discs: Engineered for strength and reliability, providing consistent performance over the valve’s lifespan.

Installation and Maintenance

Installation Process:

- Site Assessment: Detailed assessment of the operational requirements and site conditions to select the appropriate valve type.

- Custom Fabrication: Tailor-made valves to meet specific operational and regulatory requirements.

- Quality Control: Rigorous testing and inspection to ensure valves meet all performance and safety standards.

Maintenance:

- Regular Inspections: Scheduled inspections to monitor valve condition and performance.

- Repair Services: Prompt repair services to address any issues, ensuring the continued integrity and reliability of the valves.

- Spare Parts: Availability of spare parts to facilitate quick repairs and minimize downtime.

Environmental and Economic Benefits :

- Enhanced Safety: High-quality valves reduce the risk of leaks and failures, ensuring safe operation.

- Cost Savings: Long-lasting performance and low maintenance requirements reduce overall operational costs.

- Efficiency: Efficient valve designs ensure optimal flow control and minimal pressure loss, enhancing system performance.

- Sustainability: Use of durable materials and efficient designs to minimize environmental impact.

Why Choose Coteso Industrial Valves ?

- Expertise: Decades of experience in providing innovative valve solutions for various industries.

- Quality: Commitment to delivering the highest quality products, ensuring long-term reliability and performance.

- Customization: Tailored valve solutions to meet specific operational needs and regulatory requirements.

- Comprehensive Support: From design and fabrication to installation and maintenance, Coteso provides end-to-end support for all your valve needs.

-

For more information or to discuss your specific requirements, please contact our team of experts who are ready to assist you in finding the best industrial valve solutions